Produits phares

Crushing Of Silicon Quartz Facty Mining Machinery

Crushing Of Silicon Quartz. It is concluded from this research the particulate generated from stone crushing activities contain a significant amount of respirable particle. The amount of free silica in stone quartz is 85 to 97 percent that emission of particles effect to health workers. LEV has important effect in the removal of silica

Contact

Quartz Crushing Solution Eastman Rock Crusher

1. The flow of the quartz stone crushing line is: (silo) → vibrating feeder → (jaw crusher) → cone crusher → vibrating screen → finished crushed stone

Contact

Quartz crushingprocessing-LIMING Mining and Rock Technology

Quartz sand plays an important role as the core raw material in silicon production; 4. Natural crystal raw material shortages and expensive. The featured purification purity quartz sand, ultra-fine quartz powder instead of crystal meets the increasing demand for high-tech.

Contact

Quartz for carbothermic production of silicon

The source for silicon (raw materials) for the metallurgical production of (Fe)Si, is quartz and quartzites consisting of minimum 98.5 % SiO 2,depending

Contact

Processing of quartz lumps rejected by silicon industry

Feb 10, 2015This company's production was exclusively sold to a major metallurgical grade silicon producer nearby. The quartz extraction was done by removing large quartz blocks (over 100 kg) using backhoe machinery and feeding them into a jaw crusher.

Contact

SILICA DUST, CRYSTALLINE, IN THE FORM OF QUARTZ

Silica, or silicon dioxide (SiO 2 ), is a group IV metal oxide, which naturally occurs in both crystalline and amorphous forms (i.e. polymorphic; NTP, 2005 ). The various forms of crystalline silica are: α-quartz, β-quartz, α-tridymite, β-tridymite, α-cristobalite, β-cristobalite, keatite, coesite, stishovite, and moganite ( NIOSH, 2002 ).

Contact

SilicaOne The specialist in high purity quartz minerals

SilicaOne specializes in the mining,processingmarketing of performance industrial Quartz minerals,understand specific requirements and then provide not just customised raw materials but a turnkey, end-to-end industrial silica

Contact

Factory-Made Quartz Countertops Need To Be Cut Safely

Dec 02, 2019The Cambria factory in Minnesota manufactures slabs of engineered quartz for kitchen and bathroom countertops. If businesses don't follow worker protection rules, cutting these slabs to fit...

Contact

Non-occupational exposure to silica dust PMC

Occupational exposure to silica occurs at workplaces in factories like quartz crushing facilities (silica milling), agate, ceramic, slate pencil, glass, stone quarries and mines, etc., Non-occupational exposure to silica dust can be from industrial sources in the vicinity of the industry as well as non-industrial sources.

Contact

US7195184B2 Method of crushing silicon blocks Google

In a method of crushing silicon blocks, a silicon block to be crushed is heated and is then forcedly cooled. Subsequently, a crushing member which contains no metal component at least on a surface thereof is made to strike the cooled silicon block to thereby crush the silicon block. Alternatively, two silicon blocks to be crushed are heated and are then forcedly cooled.

Contact

Crushing Of Silicon Quartz Facty Mining Machinery

Crushing Of Silicon Quartz. It is concluded from this research the particulate generated from stone crushing activities contain a significant amount of respirable particle. The amount of free silica in stone quartz is 85 to 97 percent that emission of particles effect to health workers. LEV has important effect in the removal of silica

Contact

Crushing Of Silicon Quartz

Quartz Crushing Silicon. Crusher for silicon quartz dolomitemill this crusher machine can crush the raw material less than 425mm after crushing the materials will be 50100mm through the crushing of the jaw crusher machine its capacity will be 45100tph and it will take 655kw power cone crusher for for silicon quartz.

Contact

Quartz Crusher For Silicon

The first choice is to crush the quartz stone first by a jaw crusher, and then enter the double roller crusher for fine crushing. Its main products are crusher for silicon quartz, etc., and we have senior engineers for specific the product structure is subdivided into a truly good industry design, providing users with a more personal and

Contact

Crusher For Silicon Quartz

The dry quartz sand production line mainly consists of stone crushing machine and crusher for silicon quartz. The quartz sand materials will be first broken into small pieces by the crusher for silicon quartz. Next, the material will be further crushed into sand particles. Different types of crusher for silicon quartz circuit involves

Contact

Crusher For Silicon Quartz In Quarry Industris Mining company

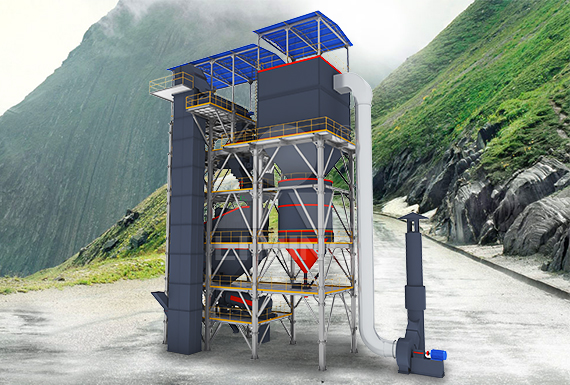

Quartz crusher is a necessary role in quartz mining process. mpl is a professional manufacturer of quartz crusher and other ore crushers. We can design the whole solution for your quarts mining and quartz quarry. Commonly quartz crushing plant consists of jaw crusher cone crusher impact crusher vibrating feeder vibrating screen and belt conveyor.

Contact

Quartz Processing,CrushingGrinding,Plant Prominer

Quartz crushinggrinding system: Silica is hard and chemically inert and has a high melting point, attributable to the strength of the bonds between the atoms. These are prized qualities in applications like foundries and filtration systems. Industrial sand’s strength, silicon dioxide (SiO2) contribution, and non-reactive properties

Contact

Quartz Silica Sand Crushing Unit In Turkey

Silica Quartz crushing and processing plant Silica Quartz crushing and processing plant consists of many different machines designed to break, crush and convert the quartz into powdered form. There are mine mills, feeders to put the quartz, crushing machines to get the desired form of quartz, grinding chambers for powder processing.

Contact

High-purity quartz production is inseparable from these

Jul 06, 2022As a commonly used process in quartz crushing, thermal crushing not only reduces the hardness of quartz blocks and crushing energy consumption, but also reduces the possibility of secondary pollution of quartz by reducing the contact time between quartz and grinding media; at the same time, micro-cracks are generated on the surface of quartz

Contact

US7195184B2 Method of crushing silicon blocks Google

In a method of crushing silicon blocks, a silicon block to be crushed is heated and is then forcedly cooled. Subsequently, a crushing member which contains no metal component at least on a surface thereof is made to strike the cooled silicon block to thereby crush the silicon block. Alternatively, two silicon blocks to be crushed are heated and are then forcedly cooled.

Contact

Silicon Valley’s co-working boom is no cure for its crushing Quartz

Jul 11, 2016Silicon Valley may be satire, but the HBO television show hits eerily close to home for many people in the technology and start-up worlds. Among the many things it

Contact

Factory-Made Quartz Countertops Need To Be Cut Safely To Control Silica

Dec 02, 2019A sign warns of silica at the door to a huge room filled with mechanical mixers. There, workers wear respirators as they combine quartz, pigments and a binder.

Contact

Using Fused Quartz in Silicon Wafer Processing Saint-Gobain

Apr 24, 2020Fused quartz is a key enabling technology for the rapidly expanding semiconductor wafer industry. Currently valued in excess of USD $9.85 billion, the global market for silicon semiconductor wafers has forecasted an enormous growth trajectory in the coming years. Estimates suggest the industry will top USD $13.64 billion by 2025.

Contact

Quartz Quartz Crushing Mills In Nigeria-HN Mining Machinery

Introduction Quartz is a mineral composed of silicon and oxygen atoms in a continuous framework of SiO4 silicon–oxygen tetrahedra, with each oxygen being shared between two tetrahedra, giving an overall chemical formula of SiO2. Gold ore processing plant, crushing quartz hardrock gold and smelting buttons to grinding machine, wet ball

Contact

Silica Quartz

Silica Quartz mine is situated outside Delmas, on the border of Mpumalanga and Gauteng. In operation since 1972, Silica Quartz is among the largest producer of high-quality silica in South Africa, used primarily in the production of glass and graded sand. The operation comprises an open pit, crushing, wet and dry screening processing plants for

Contact

Crushing Of Silicon Quartz

Quartz Crushing Silicon. Crusher for silicon quartz dolomitemill this crusher machine can crush the raw material less than 425mm after crushing the materials will be 50100mm through the crushing of the jaw crusher machine its capacity will be 45100tph and it will take 655kw power cone crusher for for silicon quartz.

Contact

Quartz Crusher For Silicon

The first choice is to crush the quartz stone first by a jaw crusher, and then enter the double roller crusher for fine crushing. Its main products are crusher for silicon quartz, etc., and we have senior engineers for specific the product structure is subdivided into a truly good industry design, providing users with a more personal and

Contact

crushing of silicon quartz

Silica Sand is quartz that over time through the work of water and wind has its overall structural integrity combine to deliver the required crush resistance of General Purpose Quartz Sand Crushing Plant With. Silica sand crushing plant brief introduction Silica sand also known as quartz sand which can be used in various industries such as

Contact

Quartz Crushing,Quartz Crusher Plant,Quartz Crusher Plant Price,Quartz

Quartz main ingredient is silica, Mohs hardness 7, translucent or opaque crystals, generally white.the mainly experiment are jaw crusher,imapct crusher,cone crusher etc. which do not meet the required final size will from the vibrating screen returns into sand making machine for re-crushing. Quartz product final size can according to the

Contact

Quartz Silica Sand Crushing Unit In Turkey

Silica Quartz crushing and processing plant Silica Quartz crushing and processing plant consists of many different machines designed to break, crush and convert the quartz into powdered form. There are mine mills, feeders to put the quartz, crushing machines to get the desired form of quartz, grinding chambers for powder processing.

Contact

Quartz Quartz Crushing Mills In Nigeria-HN Mining Machinery

Introduction Quartz is a mineral composed of silicon and oxygen atoms in a continuous framework of SiO4 silicon–oxygen tetrahedra, with each oxygen being shared between two tetrahedra, giving an overall chemical formula of SiO2. Gold ore processing plant, crushing quartz hardrock gold and smelting buttons to grinding machine, wet ball

Contact

Complete set of quartz stone crushing equipment

Aug 15, 2020The main component of quartz stone is silica. Processing quartz stone requires crushing equipment. Since the Mohs hardness of quartz stone can be as high as 7.5, a more wear-resistant and compression-resistant crusher is needed to crush it. It can crush big quartz stone to below the medium size at one time. The finished product can directly

Contact

Quartz Wikipedia

Quartz is a hard, crystalline mineral composed of silica (silicon dioxide).The atoms are linked in a continuous framework of SiO 4 silicon-oxygen tetrahedra, with each oxygen being shared between two tetrahedra, giving an overall chemical formula of SiO 2.Quartz is the second most abundant mineral in Earth's continental crust, behind feldspar.. Quartz exists in two forms, the

Contact

High-purity quartz production is inseparable from these

Jul 06, 2022As a commonly used process in quartz crushing, thermal crushing not only reduces the hardness of quartz blocks and crushing energy consumption, but also reduces the possibility of secondary pollution of quartz by reducing the contact time between quartz and grinding media; at the same time, micro-cracks are generated on the surface of quartz

Contact

US7195184B2 Method of crushing silicon blocks Google

In a method of crushing silicon blocks, a silicon block to be crushed is heated and is then forcedly cooled. Subsequently, a crushing member which contains no metal component at least on a surface thereof is made to strike the cooled silicon block to thereby crush the silicon block. Alternatively, two silicon blocks to be crushed are heated and are then forcedly cooled.

Contact

JP2005288332A Crushing method of polycrystalline silicon rod

PROBLEM TO BE SOLVED: To provide a crushing method of a polycrystalline silicon rod with a little pollution with impurities at the time of crushing. SOLUTION: The crushing method is for crushing a polycrystalline silicon rod by heating the silicon rod put in a heating furnace and then forming cracks by quenching the silicon rod and the crushing method is carried out with

Contact

Crystalline Silica Cancer-Causing Substances NCI

Feb 01, 2019An abundant natural material, crystalline silica is found in stone, soil, and sand. It is also found in concrete, brick, mortar, and other construction materials. Crystalline silica comes in several forms, with quartz being the most common. Quartz dust is respirable crystalline silica, which means it can be taken in by breathing.

Contact

Direct bonding of silicon and quartz glass using VUV/O3

Sep 30, 2018Fig. 2, Fig. 3 show AFM images of silicon and quartz glass irradiated for 0 and 15 min with areas of 10 × 10 μm 2 and 1 × 1 μm 2, respectively.Some asperities grew on the irradiated surfaces, as presented in the AFM images with the area of 10 × 10 μm 2 in Fig. 2.Statistical analysis showed that the diameter of the asperities was ∼41.3 nm, while the

Contact

Crusher Plant Silicon Quartz

silica quartz processing machinery cost YouTube. Silica is a major component of sand, rock, and miner- al ores and is quartz and in stone crushing units located at west of Iran. A size of 40 There are 29 factories that crush quartz . ca sand plants which had

Contact